In this article we’ll talk about:

The function of a Constant Velocity Joint, what they’re made of, and how to tell if the CV joint is worn and needs replacing.

The Function of Constant Velocity Joints:

The CV Axle Assembly is a part of the drive train and is responsible for sending the engine power to the transmission to the wheels. It connects the transaxle (or differential) to the drive wheels.

Most/all front wheel drive vehicles have CV joints. Many AWD vehicles have them as well. They are less common on 4WD or RWD pickups.

The Constant Velocity Joints are actually just one component of the CV Axle Assembly but generally when someone refers to the CV Joint they’re talking about the whole assembly so we’ll break down the whole kit and kaboodle.

CV stands for Continuous Velocity meaning the input speed of the axle shaft will always be equal to the output speed of the wheel hub assembly no matter what angle the joint is at. This ensures that the drive wheels will always spin at a consistent speed whether they are pivoting left or right to steer or moving up and down with the suspension system.

The Anatomy of a Constant Velocity Joint:

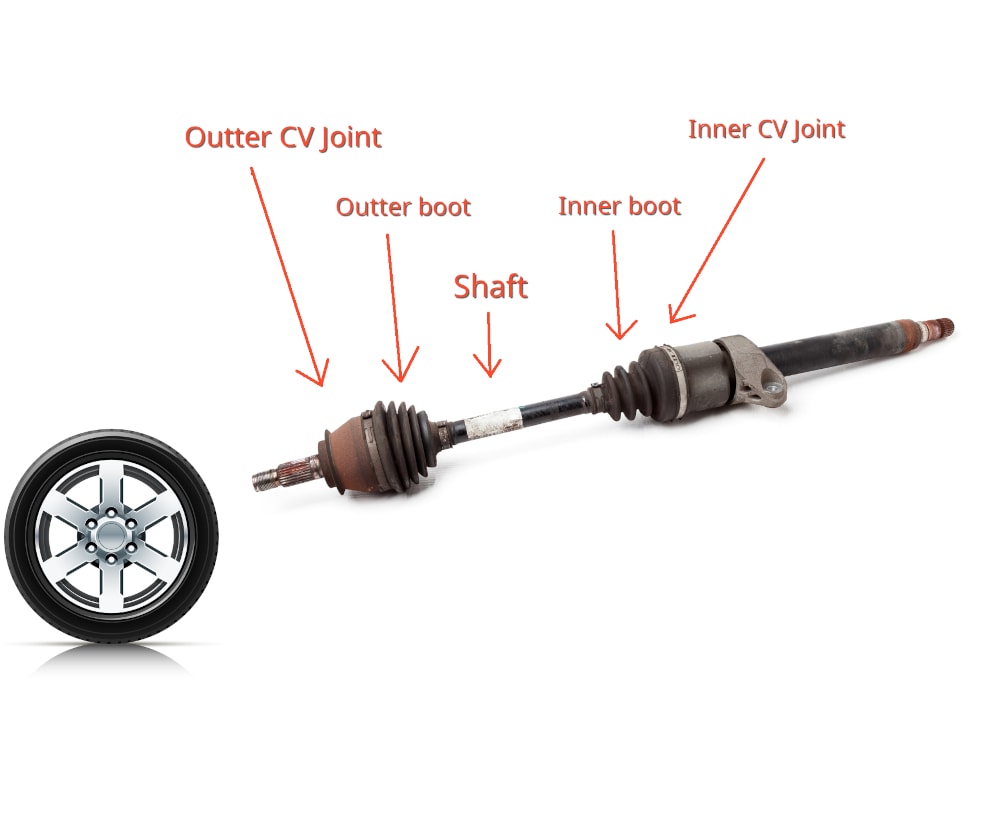

A CV Axle Assembly is made up of 4 main parts

- The Inner CV Joint – This is usually a Tripod style CV Joint

- The Outer CV Joint – This is typically a Ball style CV Joint

- The Axle Shaft – This just connects the Inner and Outer Joints

- The Rubber CV Joint Boot, Inner and Outer – These surround the inner and outer joints (respectively) to keep debris out and keep grease in.

Inner CV Joint:

Inner CV Joints are typical Tripod Style joints.

These are similar to Universal joints you would find as part of a driveshaft assembly however instead of 4 rollers they have 3. Thus the name. These rollers rotate around the needle bearings inside them and live inside the Tripod Joint housing. The Tripod housing allows the rollers some horizontal movement inside the housing parallel with the CV Axle shaft as well as some pivoting movement, allowing the axles to transfer power at a…constant velocity…(see what I did there) while the rims are turning and while the suspension moves in up and down motions.

Here is a link to the Google Patents page on Tripod CV Joints:

https://patents.google.com/patent/EP1413787A2

Outer CV Joint

Outer CV Joints are typically Ball style joints. By the name you can assume that correctly that these joints use ball bearings rather than rollers and needle bearings. This is because the outer CV Joints do not need that same horizontal movement like the inner joints. They do however allow much more rotational or swinging movement being that they are mounted much closer to the wheels and experience more extreme angles. The ball bearings move inside of machined channels cut into the inside wall of the joint housing and this is usually where you’ll find the most wear with these bearings.

Here is a link to the Google Patents page on Ball style CV Joints:

https://patents.google.com/patent/EP2505862A1/en

Shaft

The output shafts look like… well, a long piece of metal.

Boots

There is an inner cv joint boot and an outer cv joint boot. Each protective boot surrounds the inner and outer joint and protects them from dust and debris as well as contains the joint grease which lubricates the metal surfaces inside the joints.

Here’s a fantastic video of a guy disassembling a CV Axle Assembly and explaining each part:

Drivetrain differences

FWD

The CV Axles connect the transaxle to the wheels to drive the car. Most front wheel drive cars have a transverse mounted engine and use a mechanism called a transaxle (basically it’s a differential shoved inside of the transmission) to transfer power from the transmission to the rims via the CV.

RWD

Rear drive cars are a little different in that the motor is mounted longitudinally (inline with the car) along with the transmission. The power from the engine is then sent through the transmission and subsequently through the drive shaft and into the rear differential which then splits that power to the rear wheels via the CV Axles to propel the vehicle.

AWD

All wheel drive vehicles typically utilize a transaxle in the front to power the front wheels but also send an output shaft to the rear of the vehicle to a rear differential and CV Axles to power the rear simultaneously.

4WD

A 4WD vehicle will usually only have CV joints in the front, but a solid axle in the rear.

Most 1/2 ton and light duty pickup trucks these days utilize Independent Front Suspension systems rather than a solid front axle due to the more comfortable ride quality. Thus the need for CV Axles to power the front tires while in 4 wheel drive. They send power to the front through a transfer case (mounted behind the transmission) and subsequently to the front differential via the front drive shaft and then the CV’s.

Can a bad CV Joint Affect the Transmission?

It can! In some circumstances….

When a CV Joint wears out, a common symptom is vibration and even shaking felt through the steering wheel. If left unnoticed or simply neglected and ignored for long enough this shaking can cause the seal where the inner CV Joint meets the transaxle to fail and leak transmission fluid. And though a worn CV Joint may not seem like a critical repair to make right away, a transmission without fluid will fail and is a much costlier repair than the CV Joints.

So if you notice grease around the boots or near the axle-area, it might be worth jacking the car up and taking a closure look!

How to check if your CV Joints are worn out and need to be replaced

Vibration

The first and usually the most obvious symptoms that it’s time to replace your CV’s is when you feel a shaking or vibration upon acceleration, however this can be caused by other factors other than the CV Axles.

Clicking

Something else to listen for is if you hear a clicking noise coming from the front end. It may be hard to pinpoint during normal driving but an easy way to check is to drive in circles (preferably in an empty parking lot and not on the road) with the steering wheel at full lock. If your CV Joints are beginning to show excessive wear you will hear a consistent clicking noise as you drive. If the wear is excessive it could turn into a squeak or squeal.

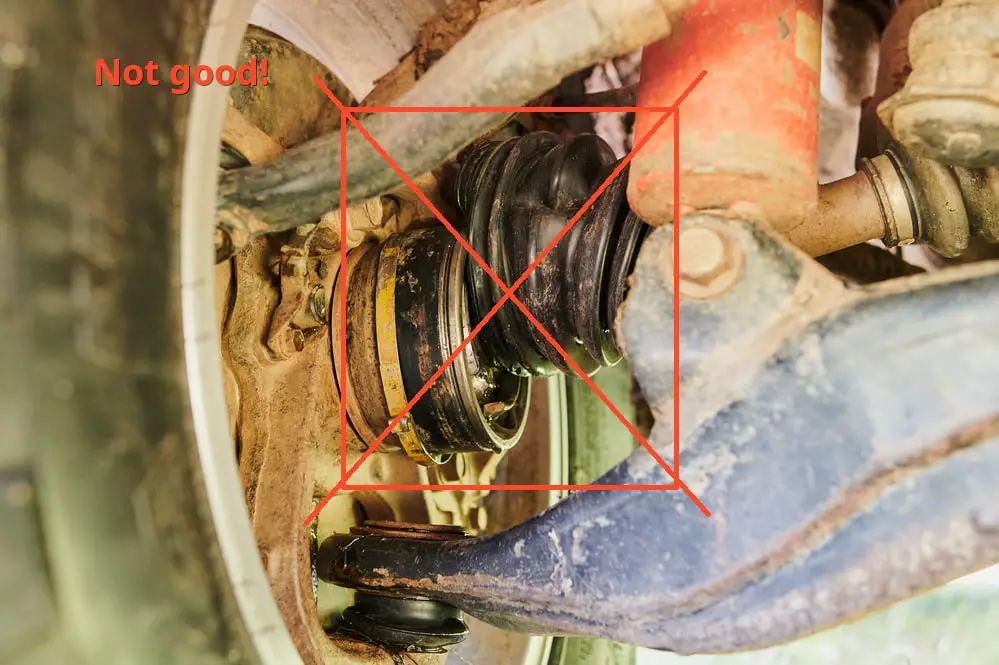

Boot failure

A visual indicator that it’s time to replace your CV Joints will be a torn or missing rubber CV Joint boot. Once the boot is compromised the joint may collect dust or debris which will cause premature wear. Often when a boot gets torn it will fling grease into the wheel well so keep an eye out for that as well. A lack of grease means the joint may not be properly lubricated and will lead to failure.

IMPORTANT

As always, if you are not highly confident in your mechanical abilities, please do not attempt to repair your cv joint yourself (or hire Joe-Shmo down the road who said he’d do it for $40 and some beer). Performing these repairs incorrectly could cause serious damage to your vehicle and worse put yourself and others on the road at risk. If you think your car may need repair but you’re unsure, do not hesitate to get your vehicle inspected.