In this article we will explain:

- What Ball Joints and Tie Rods are

- Their respective functions and anatomies, as well as

- Their common failures

- How to tell if they’re worn out and,

- A rough idea of how much it might cost to replace them!

Different Functions

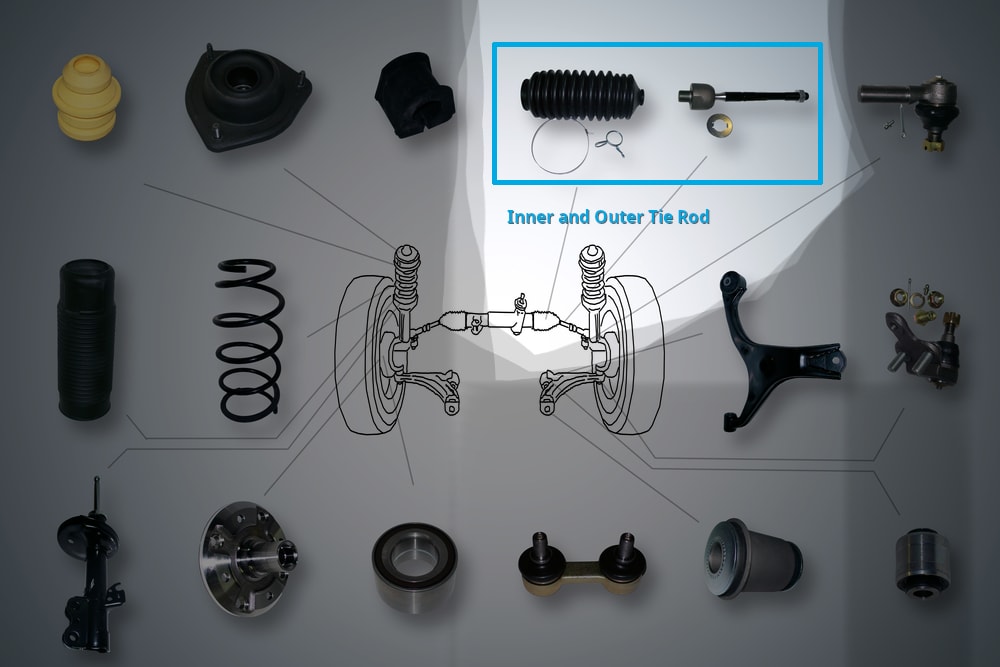

The Tie Rod ends connect the steering system to the front wheels via the steering knuckle. It pushes and pulls on the steering knuckle in order to rotate the wheels laterally and turn the vehicle. The outer tie rod ends are also adjustable to assist in wheel alignment. Without the tie rod ends, the steering gear would not be connected to the steering knuckle allowing the steering wheel to turn left or right.

The Ball Joints are the critical connection point between the car’s suspension system and the front wheels, also via the steering knuckle. They must support the weight of the vehicle while also allowing the steering system and suspension system to work in concert with one another. They do this by allowing the front wheels to simultaneously move freely along the vertical plane (moving up and down with the suspension system) while also pivoting left and right (steering the car) at any point along the travel of the suspension.

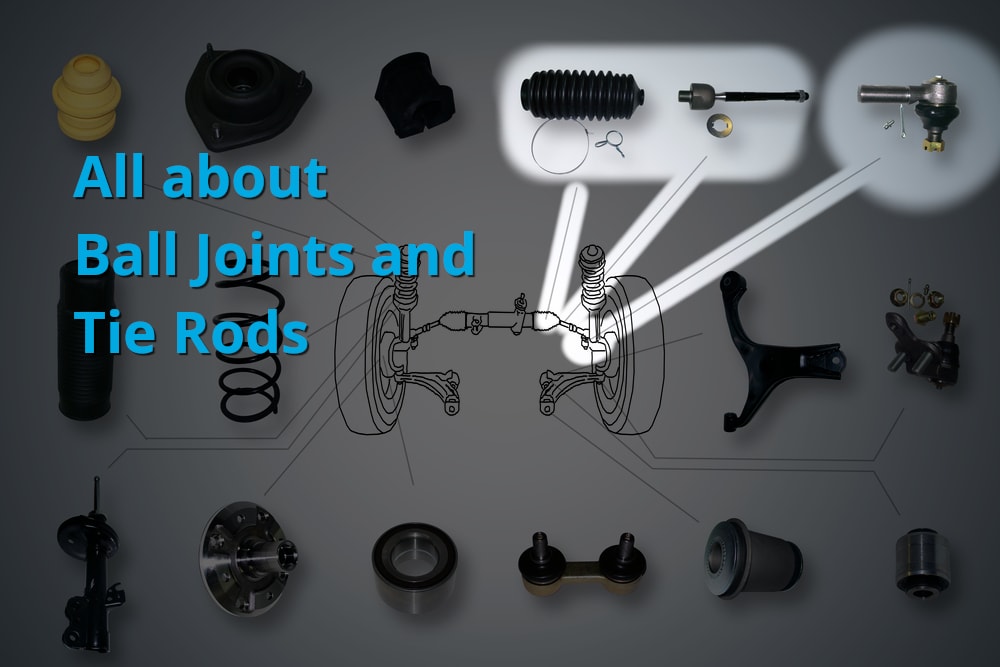

Anatomy of Ball Joints and Tie Rods

A Ball Joint is made up of four parts:

- The Ball Stud – Spherical metal part that looks like a ball

- Housing Body aka Socket – Where the ball stud lives

- The Crown or Pressure Plate – Keeps the ball stud tight and secure inside the housing

- The Boot – Rubber part that protects the ball joint

The Ball Stud is fairly self explanatory. It is the spherical metal part that looks a bit like a ball. The Ball Stud lives inside of the Housing Body where (when properly lubricated) it can rotate and spin freely but should not move up and down (parallel to the stud) inside the housing and should not come out.

The Crown aka Pressure Plate applies pressure to the ball stud inside the housing to prevent that up/down movement.

The Boot is the flexible rubber part surrounding the housing body which protects the exposed part of the ball joint by keeping debris out and holding grease in.

A tie rod is made up of 3 parts primarily.

- The Inner Rod End – Connects to the Pitman Arm or other steering component

- The Outer Rod End – Connects to the steering knuckle

- Shaft – Joins the two rod ends

Each rod end has a ball stud joint (very similar to the ball joints but smaller) at one end which connects to either the pitman arm or other steering component (inner rod end) and the steering knuckle (outer rod end) respectively. These joints allow the tie rod to move up and down with the suspension to ensure the vehicle can be steered at any point along the suspension travel.

Here’s a tip

If you’re ever curious to learn about the more technical aspects of an automotive part or system, Google Patents is a massively helpful resource.

Here’s the link to the Google Patents page on Ball Joints:

https://patents.google.com/patent/US3850443A/en

Can you drive with a worn Ball Joint or Tie Rod?

Both the tie rod and ball joints are absolutely critical components to the operation of your vehicle. While you can still drive with a worn out tie rod or ball joint it is quite dangerous and the worn parts should be replaced ASAP.

The reason it is so dangerous to drive with a worn outer tie rod or inner tie rod end is because they directly connect the front wheels to the steering linkage system and if one of these joints fails you could lose the ability to steer the vehicle.

The Ball Joints essentially hold the wheels to the car itself. When a ball joint fails you often see a car with the front wheel folded underneath or fallen away from the car. Should all of the ball joints fail simultaneously the wheel could suddenly and violently uninstall itself from the car.

Don’t be that guy…

Ball joint and Tie Rods will fail in two ways. By becoming too loose or too tight.

Here’s how to check if your Tie Rod needs to be replaced

Too Loose

A loose tie rod end can cause a clunking or clicking noise coming from the front end while steering. If you can grab the tie rod and move it around by hand while it’s installed on the vehicle, it’s time to replace your worn tie rod ends. Look for dirt coming from the rubber boot as well.

Too Tight

A tight, frozen or seized tie rod will cause squeaking or creaking noises to come from the front end on the side corresponding to the worn part and can also increase the amount of effort required to turn the steering wheel. This tightness can cause added wear on the other steering components leading to the need to replace them earlier or even premature failure.

Rough cost to repair the outer tie rod end

The cost to replace a tie rod can vary dramatically depending on whether you do the work yourself or have it done professionally. There is also a large disparity between the cost of low quality parts and high quality parts. Cheap tie rods can run as low as ~$50 but the old adage of “You get what you pay for.” rings true. Quality parts for ~$100-$150. Most of the cost in replacing these parts will be in labor but shouldn’t be more than ~$500 typically (don’t quote me on that).

For example, a 2010 Toyota Camry tie rod end can be had for $55 on Autozone at the time of this article.

You can of course save some money by doing the work yourself if you’re confident in your abilities. You should always replace both tie rods and be sure to get an alignment after installation.

How to check if both Ball Joints work as they should

Jack the vehicle up, stick a prybar under the tire, and pull upwards. Check for any movement. Read more about worn or bad ball joints.

Too Loose

The ball stud moves up and down inside the socket, if it becomes too worn it can lead to joint failure causing the wheel to uninstall itself from the car….

A loose ball joint will move inside of the socket in parallel with the stud. With the car on jack stands and the front wheels off the ground, try to move the wheel up and down. If there is play or a clicking noise, it’s probably time for new ball joints.

If you notice excessive tire wear, this is another good indicator of a worn ball joint. Look especially at the inner and outer treads on the rubber.

Too Tight

Debris or rust can get into the pivot point socket causing it to seize or freeze, not allowing it to move freely causing the vehicle to track improperly on the road and requiring constant steering input and correction in order to maintain a straight line. The steering wheel will not automatically return to center as it should.

Ball joint replacement cost

Again, the cost to replace a ball joint can vary dramatically depending on whether you do the work yourself or have it done professionally. Cheap ball joints can be found for ~$50 and quality ball joints for ~$100 – $200. As with tie rods most of the cost will be in labor should you decide to hire a professional but shouldn’t be more than a few hundred dollars.

IMPORTANT

If you are not highly confident in your ability to diagnose these issues or install the parts correctly, please do not hesitate to hire a professional shop to do the work for you (and no, your buddies cousin down the road does not count). You DO NOT want to be the person to cause an accident and potentially endanger others because you forgot to tighten a nut or some other stupid reason.