Replacing a turbocharger is a job that with some simple mechanic skills and basic tools, most people can do in a weekend. But there’s a few things to remember. In this article we’ll talk about the signs of a failing turbo, what causes failure, and 5 crucial tips.

Whether you have a gasoline or diesel engine, the turbocharger is an integral part of the entire application. But for some reason, the turbocharger might fail or fail unexpectedly. While it’s not exactly difficult to replace a turbocharger, the process requires a moderate amount of patience, expertise, and a host of tools.

Also, the procedures in replacing a turbocharger will vary from one vehicle to the next. It also depends on the type of motor or if you’re dealing with a diesel car or truck.

What are the signs and symptoms of a faulty turbocharger?

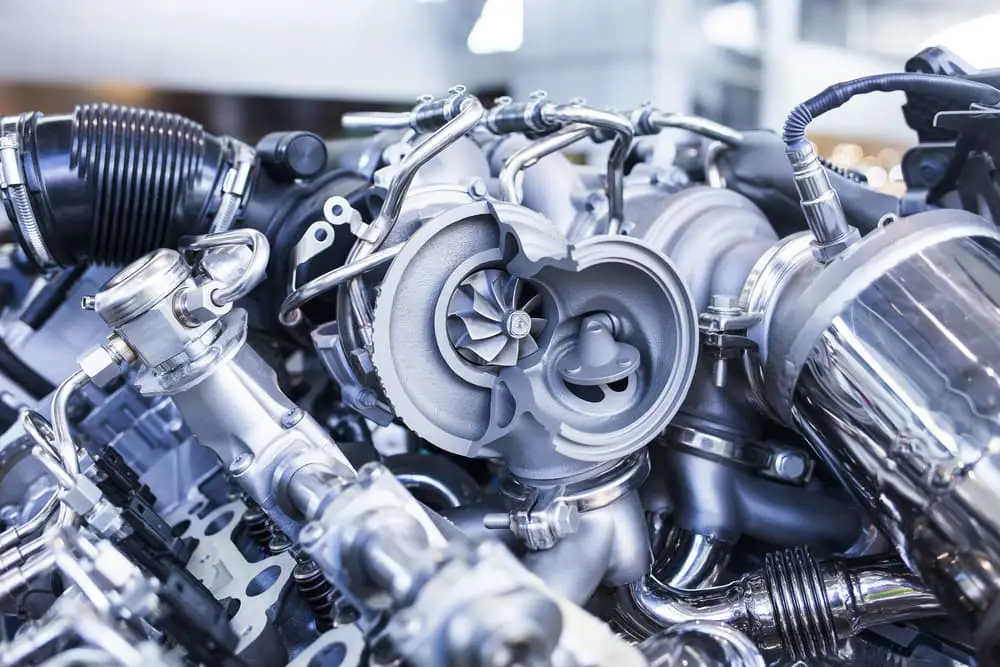

Turbochargers are a forced-induction, turbine-driven device that pumps extra air inside the engine. Turbos are powered by turbines that spin via the motor’s exhaust gasses. When talking about internal combustion motors, more air means more power. Forcing the engine to ingest more compressed air (and fuel), the engine produces higher amounts of power and torque.

When something goes wrong with the turbo, performance issues may crop up including:

1. Slow acceleration.

Since the primary function of a turbocharger is to produce more power, a broken or failing turbo results in a lack of power and acceleration. If your car accelerates slower than it used to be, you might be dealing with a bad turbo.

2. Illuminated check engine light.

In most cases, a bad or failing turbocharger will illuminate the check engine light or engine warning light in the console. However, the check engine light can mean many things. The vehicle ECU should be scanned for fault codes to determine the fault. In most modern cars, having a P0234, P0235, P0236, P0238, P2262 or P0299 DTC code means the engine is dealing with a bad turbocharger.

3. Loud noises under the hood.

Do you hear loud whining noises under the hood as you step on the gas pedal while accelerating your vehicle? Or do you hear a high-pitched whining noise when revving the motor? It’s the sound of a turbo in misery. The loud noises are caused by a lack of lubrication in the turbo bearings.

4. Thick smoke from the exhaust.

It’s often combined with slow or sluggish acceleration and loud whining noises. Thick smoke from the exhaust is a sure sign of a turbocharger problem. Small cracks in the turbo housing may allow the oil to leak into the exhaust system. When this happens, the problem is manifested by thick exhaust plumes. It’s also a sign of a bad turbo.

Pro Tip A bad turbo boost sensor can produce also these symptoms.

What causes turbo failures?

When a turbo goes bad, the first thing you need to do is to locate the source of the problem. You see, turbos don’t go deteriorate without reason. In most cases, a turbocharger failure is caused by other factors than normal wear and tear.

- Oil starvation is the primary cause of turbocharger failures.

The oil that protects engine parts is also responsible for protecting the internal components of a turbocharger. As the main shaft rotates to an average of 4,000 rotations per second, there’s a massive buildup of heat in the assembly. As such, it needs proper amounts of clean oil to reduce friction and heat buildup in the shaft assembly. If there’s no oil due to blockages in the oil feed pipe, the turbo is destined for early death.

- Dirty or contaminated oil can also be blamed for premature turbocharger damage.

Dirty oil contains massive amounts of dirt, gunk, debris, and/or metallic contaminants – things that a turbocharger doesn’t like. Contaminants or metal filings suspended in dirty oil can scar or scratch the bearings on the main shaft. This affects the performance and service life of the turbo.

- Repeated ‘hot stops.’

This especially holds true for high-performance turbocharged vehicles. Hot stops occur when you turn off the engine abruptly without allowing the turbocharger to cool. Since the turbocharger depends on a steady supply of clean oil for cooling, shutting off the engine will leave the turbo starving for oil. If the main shaft is still hot and is resting on a particular area, it can bend and cause an imbalance in the entire system.

5 things to remember when replacing a turbocharger

Dealing with a bad turbo? It’s not the end of the world. Here are some important tips to remember when replacing the turbo in your vehicle.

1. Purchase the correct part.

It doesn’t matter if you’re buying an OEM, replacement, or aftermarket part. The important thing is to buy the correct turbo for your vehicle. Installing the wrong part can lead to serious consequences. Remove the old turbo from your engine and check the nameplate. You should determine the turbo model, part number, and/or the vehicle parts number before buying a new turbo. If you don’t know what turbocharger your car uses, start here.

2. Replace the air filter, oil filter, fuel filter, and the engine oil before installing a new turbo.

Make sure to only use the specified oil grade for your vehicle. Using the wrong type of oil may also lead to engine and turbo damage later on. Your Owner’s Manual will tell you the correct grade to use.

3. Double-check the air cleaner housing and the air filter.

Make sure there are no foreign objects, contaminants, or debris.

4. Never use a liquid sealant when installing gaskets for the turbo’s oil supply or drain outlets.

Only use the supplied OEM gaskets to ensure a gas-tight seal. Liquid sealants can enter the oil supply and block the flow of oil. Also, make sure to remove old gasket material from the oil flange fittings and exhaust manifold.

5. Check and double-check the oil supply and drain hoses before installing a new turbocharger.

Remember that oil hoses should be clean and free from cracks or damage to ensure a steady supply of oil during operation.

Conclusion

After installing a new turbo, make sure to prime the unit by injecting clean engine oil into the oil feed hole and turning the rotor assembly by hand. Remember that a lack of oil priming during fitting can damage a new turbo prematurely.