Matt here with ScannerAnswers bringing you a guide on what a turbo boost sensor (TBS) is, the common OBD2 trouble codes (DTC) associated with a failing one, and some common locations on your diesel 7.3 or 6.0 Powerstroke.

So what are they?

The turbo boost sensor (or TBS) is similar to the MAP (manifold absolute pressure) sensor. The only difference is the application. Naturally-aspirated engines will normally use a MAP and MAF sensor. This allows the ECU to measure the barometric pressure and airflow volume to deliver the ideal air/fuel ratio under various operating loads.

But turbocharged engines are different.

In this case, the motor makes use of a turbine or compressor to pump more air inside the intake manifold. Turbocharged or supercharged motors will typically use a combination of sensors to measure the air pressure. This includes the MAP, MAF, and BARO (barometric pressure) sensor. But some engines have a turbo boost sensor in place of the MAP sensor, while others will have one or both.

What does a turbo boost pressure sensor do?

The turbo boost sensor measures the boost pressure in the intake manifold. This allows the ECU to determine the air pressure information at any given moment. Turbocharged or forced-induction motors have a higher air charge. The ECU needs a sensor that is capable of adapting to positive and negative pressure to provide the ideal air/fuel ratio. This where the TBS enters the fray.

The boost pressure sensor controls the boost level inside the intake manifold. Similar to the MAP sensor, the boost sensor measures the absolute pressure and monitors the speed and airflow pressure in the intake. The ECU utilizes the readings of the sensor to calculate the air density and mass air flow rate. This allows the ECU to advance or retard the timing depending on the driving situation.

What are the symptoms of bad one?

The symptoms of a failing boost pressure sensor will depend on the type of engine and vehicle model. But in most cases, the primary symptom is a check engine light and P0235, P0236 or P0238 trouble code.

If you use an OBD-II scan tool to read the trouble code DTC, the definition of the P0236 code is Turbocharger Boost Sensor Circuit Range/Performance.

This means the ECU is detecting abnormal readings from the turbo sensor. The ECU will normally compare the readings of the boost sensor with the MAP or barometric sensor when the vehicle is idling, when the key is ON and OFF, and before starting the vehicle. If the ECU detects out-of-range values in the turbo sensor, it will trigger the check engine light and P0236 code.

Next to the check engine light, the most noticeable symptoms of a faulty turbo boost sensor are lack of engine power and poor acceleration. This is mainly caused by the ECU which disables the turbo boost to protect the engine. Other symptoms include rough idling, hesitation, and hard starting.

What causes a turbo boost sensor to fail?

The main reasons are contamination and normal wear and tear. If there’s a check engine light, it could also mean the turbo boost sensor is slow to respond and may need to be replaced. At this point, the sensor is still working but is clearly starting to fail. If this is the case, the only remedy is to replace it.

And since the turbo boost sensor is exposed to the intake charge, the sensor itself is prone to dirt, sludge, and contamination. If the sensor is covered in thick dirt, it won’t be able to measure the air volume in the intake manifold. When this happens, the check engine light may also turn ON. If the sensor is still working or the values are within range, the problem can be solved by removing the sensor and cleaning it manually.

Don’t forget to check the hoses

If you’re scratching your head tracking down a low boost or lack or power, then don’t forget to check your hoses! On older vehicles especially vacuum hoses close to the intake or engine block get warm. Over time they will crack and let some boost escape. Running a vacuum test might help you here!

Where can I find the sensor?

While this is not a comprehensive list, it is the most common vehicles we’ve found that need to have this pressure sensor checked, cleaned, or replaced. Below you’ll find a few of the locations highlighted

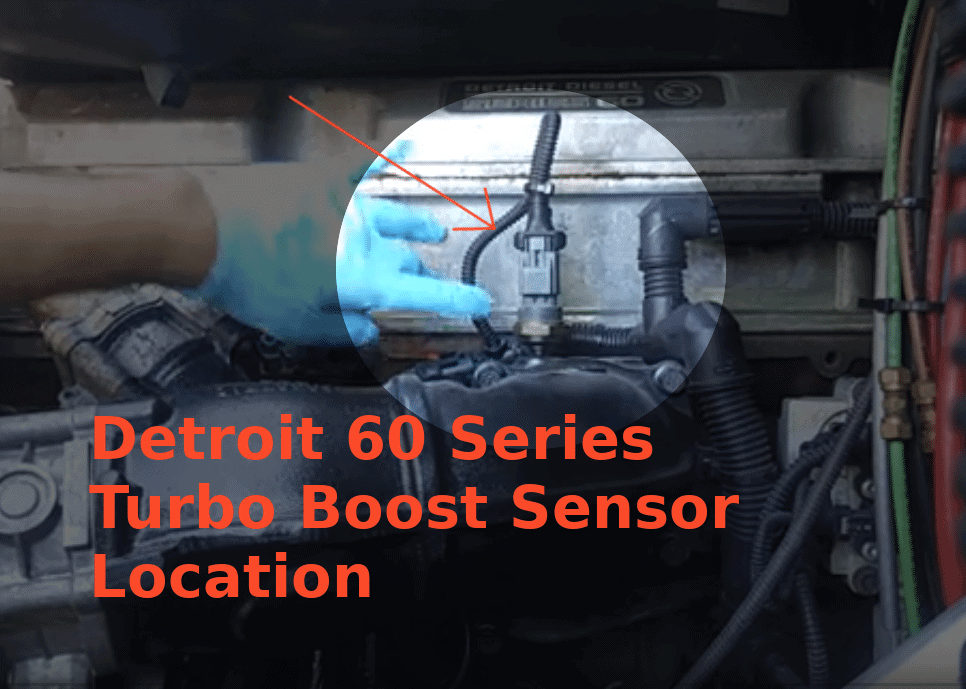

Detroit 60 series turbo boost sensor Location

First off, we have to give credits to the screenshot to Vic Med and his Youtube video showing how to replace this TBS on a Detroit Diesel. Check it out if you’ve got a truck having turbo issues!

You can find the Detroit 60 Series Boost Sensor on the driver’s side, mounted to the intake manifold near the EGR valve. Screenshot below to help:

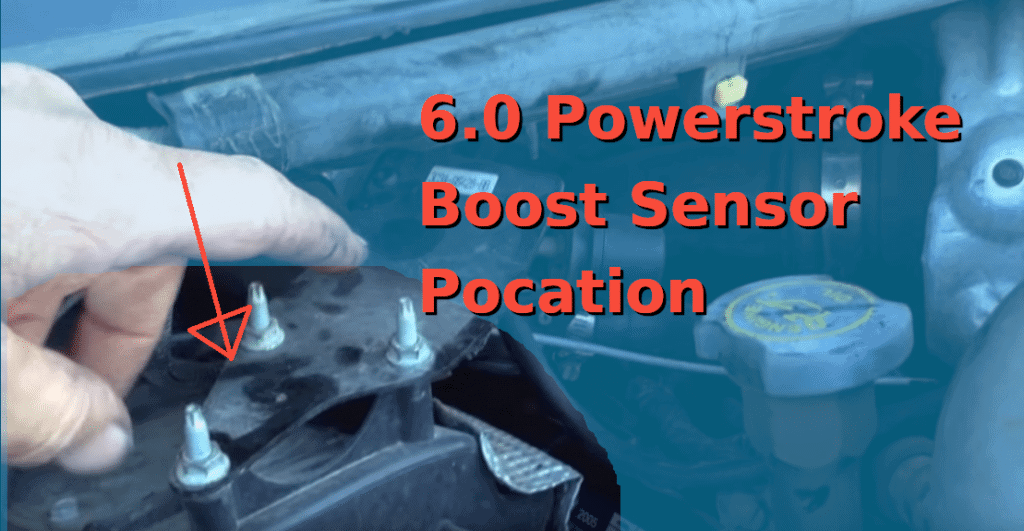

6.0 powerstroke turbo boost sensor location

DieselTechRon has a solid video troubleshooting a low boost on a 6.0 Ford. The screenshot below is from his video showing the location of the EBP / Boost Sensor.

First, the MAP sensor connects to a hose on the passenger side of the intake manifold. It’s small, and runs to the passenger side into the mess of HVAC stuff (don’t get confused by the deareation line from the EGR cooler that runs to the degas bottle). Then there’s the EBP sensor, which is somewhere around the FICM on the driver’s valve cover, it’s on the end of a metal tube that runs up from the front of the driver’s exhaust manifold. The BARO sensor is in the cab, IIRC it’s around the e-brake pedal.

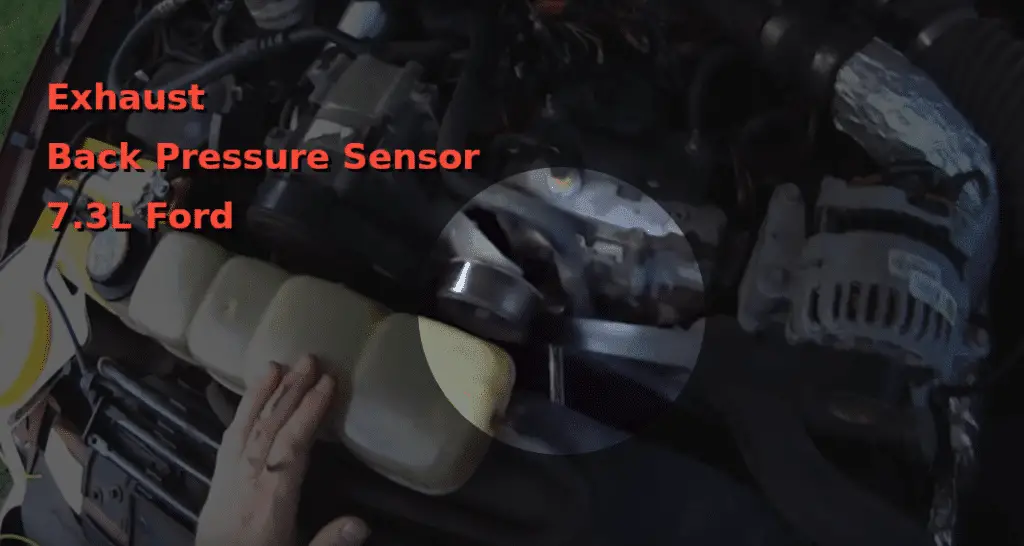

7.3 turbo boost sensor location

How do I clean the boost sensor?

Before getting into this guide, I’d recommend you check out DieselTechRon’s (RIP friend) guide to troubleshooting a P0299 on a 6.0L Powerstroke diesel. This will give you a better understanding of what you’re looking for. Video from Youtube below.

The process is no different from cleaning the MAF or MAP sensor. All you need are a couple of basic hand tools and a commercially-available MAF sensor cleaner. I like using the No products found. for this job. This powerful yet gentle cleaner is formulated with Cozol technology that literally dissolves dirt, grime, and grease without harming sensors and plastic parts. It also dries faster than other cleaners so you can get back on the road in no time!

- Park the vehicle on safe and level ground. Engage the parking brake and lift the hood open.

- Locate the turbo boost sensor. It is usually found in the intake pipe near the throttle valve. If you can’t find it, consult the service manual.

- Gently pull and remove the electrical plug from the sensor body. You may have to use a flat screwdriver to push the lock pins before removing the socket.

- Loosen and remove the locking bolts/screws using a wrench or basic socket set. Most are held in place by two screws.

- Carefully remove the sensor from the intake manifold.

- Use the sensor cleaner to remove all traces of dirt and grime on the sensor. Do not drop the sensor, and do not touch the sensor element with your bare hands. Simply spray, wipe off the excess using a microfiber towel, and allow to air dry for at least 5 minutes.

- Reinstall the sensor in the stock location. Tighten the screws/bolts sufficiently. Do not overtighten!

- Now is the perfect time to inspect the wiring and electrical connectors. Check for loose, broken, or frayed wiring. Most of the problems associated with a faulty turbo sensor are electrical by nature and are most likely caused by broken or frayed wiring.

- Connect the electrical socket to the sensor.

- After making sure everything is bolted together, start the motor and let it idle. Take the car for a short test drive and check to see if the check engine light returns. If the problem is caused by a dirty or clogged sensor, cleaning it will instantly restore engine performance.

But if you need the replace the turbo boost sensor, make sure to buy an OEM part that is an exact fit to the make, model, and engine type in your vehicle.

Clean verses Replace?

Keep in mind that these sensor cost anywhere from $30 to $60 bucks to replace. So honestly if you are sure the BPS is the issue, it’s not a bad idea to just replace it rather than mess around with cleaning it.

How do I test the supply voltage in the boost pressure sensor?

If you suspect a voltage problem in the turbo boost sensor, you can check it using a basic multimeter.

- Disconnect the electrical plug from the sensor body. When checking the supply voltage, you don’t need to remove the sensor from the manifold.

- Set the multimeter to DC voltage.

- Turn the ignition to the ON position and leave it there.

- Use the multimeter to test the supply voltage in PIN C (3) and ground A (1).

- The supply voltage should be approximately 5V.

- If the reading is below or above 5V, this means the problem is in the supply voltage. Check for broken or frayed wiring.

Conclusion

Hopefully this guide to the understanding the turbo boost sensor in your diesel or turbo-charged vehicle has helped shed some light on this. As always we recommend using an OBD2 scanner that will help pinpoint where your low boost is coming from.

-Matt