Engine Fault Codes, DTCs, PIDs and more!

OBD2 scanners encompass a wide range of functionalities dependent upon its status as either a basic code reader or an advanced scan tool. While both OBD2 models prove to be immensely valuable to vehicle owners, there is a range of divergences between the two.

The more basic code readers are limited to solely reading and clearing DTCs (diagnostic trouble codes) while the more advanced OBD2 scanning tools have the ability to record data and view in real time, in addition to providing an assemblage of highly specified knowledge. Advanced OBD2 scanning tools also have the ability to enable vehicle owners’ clear access to bi-directional tests and controls along with other advanced functionalities.

While an advanced OBDII scanning tool is unquestionably relevant to car ownership, the more basic OBD-2 scanners offer an elemental and essential functionality to vehicle owners in a no-frills, bare-bones fashion. With its ability to read and clear codes and access data on the vast array of makes and models of vehicles produced post-1996, a basic OBD2 scanner is an affordable device that offers car owners the critically important ability to self-diagnose common automobile systems issues without having to consult costly mechanics or automotive shops.

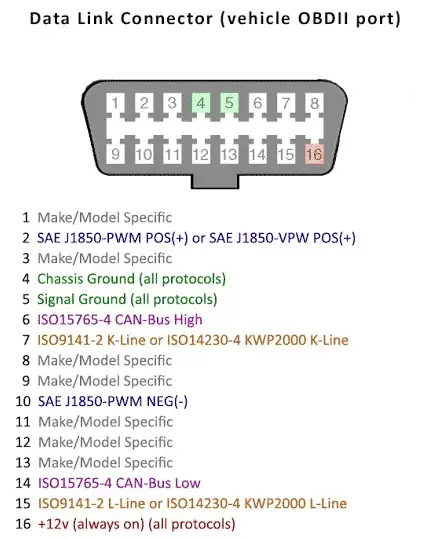

Connecting to the On-Board Diagnostics Port

OBDII standardized, universal nature makes them effortlessly easy to use. Operated by a common connector defined by SAE J1962, the operation requires only a simple insertion of a universal plug into a vehicles’ OBD-2 diagnostic connector.

A cursory OBD2 scan yields a myriad of information that is immensely valuable. OBD2’s data results will directly point car owners to specific systems or components within their vehicles that have malfunctioned or require basic attention. Within just a few seconds time, car owners are able to pinpoint specific vehicle problems and save considerable time, expense, and unnecessary frustration in determining the cause of check engine lights and other problems.

Using Your OBD Scanner Diagnostic Tool

When utilizing your wireless OBDII scanner, there are a number of things that you need to look out for to ensure a successful and effective test of your vehicle. Simply follow the easy instructions below to ensure a successful diagnostic run of your vehicle

- Ensure that you have plugged the appropriate basic scan tool into the OBD II connector under the dash

- Place the key into the ignition and turn the key on to power up and initialize the OBD2. Ensure that you do this without actually starting the vehicle’s engine

- Subsequently, start the vehicle and proceed to follow the instruction manual’s code reading procedures

- The scan tool will request a range of information from you including the vehicle’s VIN, vehicle make and model, and the type of engine.

- Following the onscreen instructions, input the correct answers to the questions

- Following the directions on the screen, simply press scan and wait for the diagnostic results to come back and inform you what issues the vehicle is experiencing

- At this point, you will be afforded the opportunity to read and erase diagnostic trouble codes, check to see completeness of readiness monitors, and view engine data in real time for an in-depth and comprehensive look at the functionality of the vehicle’s systems

- A comprehensive list of universal DTCs (diagnostic trouble codes) is provided for you at the bottom of this article. Also included is an easy to read graph that lists common acronyms and their respective meanings.

- If you need further information about individual DTCs, double check the instruction manual or CD-ROM that came with the OBD2 scanner. Additionally, you can also perform a simple web search by keying in the code and obtaining a simple explanation online

- Upon establishing the diagnostic trouble codes for your vehicle, you can utilize the information to make informed purchases of essential parts to repair your vehicle or you can share the information with the mechanic fixing your vehicle as a way to corroborate his own independent diagnostic findings

- Error codes are also known as fault codes and DTCs (diagnostic trouble codes). These codes are stored within the on-board diagnostic computer system. Stored within the on-board computerized diagnostic system in response to issues found within vehicle systems, these codes result from the system finding specific vehicle problems that require addressing.

A comprehensive summary and explanation of all the relevant information you need to successfully complete your OBD2 vehicle scan is compiled below in easy to view charts and pictures.

Types of Error/Fault/Trouble Codes

A fault code is an alphanumeric value relating to a specific type of fault found within a vehicle’s system. The list of fault codes was created by the Society of Automotive Engineers, also known as SAE, for all vehicles manufactured after 1996 that are required to be compliant with OBD2 specifications.

SAE-defined trouble codes are broken down into 4 specific categories as follows:

- Powertrain (P) codes relating to emissions, engine, and transmission systems

- Body (B) codes relating to lighting, airbags, and climate control systems

- Chassis (C) codes relating to electronic suspension, anti-lock brake systems, and steering systems

- Network Communications (U) codes relating to controller area network modules

Trouble codes from these 4 specific categories are further broken down into the following two basic groups of fault codes:

- Generic/Global codes: Required for basic emission fault diagnoses, these codes are identified by a 0 numerical value as the second digit, indicating a universal commonality to all vehicle makes and models.

- Enhanced/Manufacturer-specific codes: Designated with a numerical value of 1 as the secondary digit, these codes indicate a unique association to specific vehicle makes and models.

Most Common Engine Fault Codes

| P0420 | Low efficiency Catalyst System |

| P0171 | Fuel-Trim System Lean-Bank One |

| P0401 | Insufficent flow to EGR (Exhaust Gas Recirculation) |

| P0174 | Fuel-Trim System Lean-Bank Two |

| P0442 | Smaller leak detection in EVAP (Evaporative Emission Control System) |

| P0300 | Random misfire detection in Engine |

| P0455 | Larger leak detection in EVAP (Evaporative Emission Control System) |

| P0440 | EVAP Evaporative Emission System |

| P0141 | H02S (Oxygen Heater Sensor)

Performance Bank One, Sensor Two |

| P0430 | Catalyst system: Low-efficiency Bank Two |

| P0135 | (H02S) Oxygen sensors: Performance Bank One, Sensor One |

| P0446 | EVAP (Evaporative Emission System)

“Solenoid” Valve-Control |

| P0128 | Thermostat for coolant regulation |

| P0301 | Misfire detected in cylinder 1 |

| P0411 | Erroneous purge-flow in Evaporative Emission Control System (EVAP) |

| P0133 | Oxygen-sensor sluggish response: Bank 1, Sensor 1 |

| P0303 | Misfire detected in cylinder 3 |

| P0304 | Misfire detected in cylinder 4 |

| P0302 | Misfire detected in cylinder 2 |

| P0325 | Powertrain Control Module “knock-sensor” circuit |

| Powertrain Codes |

| P0xxx: Generic |

| P1xxx: Specific to manufacturer |

| P2xxx: Generic |

| P30xx to P33xx: Specific to manufacturer |

| P34xx toP39xx: Generic |

| Chassis Codes |

| C0xxx: Generic |

| C1xxx: Specific to manufacturer |

| C2xxx: Specific to manufacturer |

| C3xxx: Generic |

| Body Codes |

| B0xxx: Generic |

| B1xxx: Specific to manufacturer |

| B2xxx: Specific to manufacturer |

| B3xxx: Generic |

| Network Communication Codes |

| U0xxx: Generic |

| U1xxx: Specific to manufacturer |

| U2xxx: Specific to manufacturer |

| U3xxx: Generic |